Product About MedO

Medical Oxygen Generators (MedO)

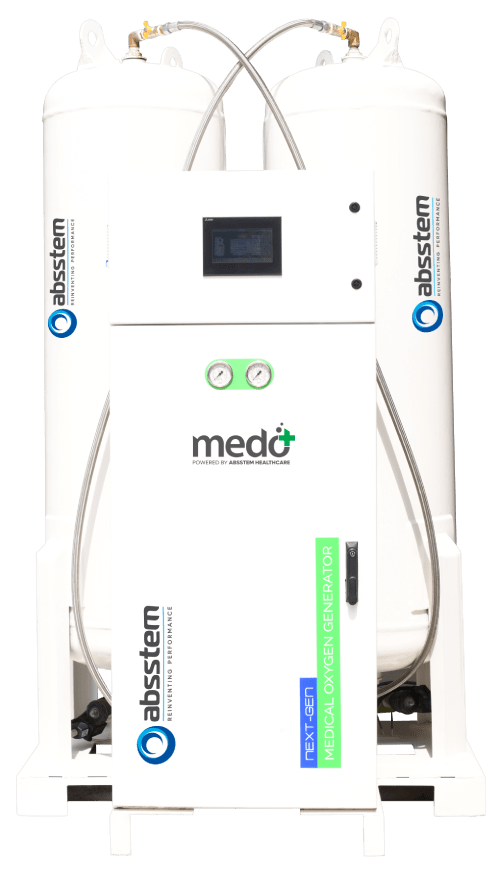

MedO, the smart and efficient oxygen generator, aims to help medical facilities produce their own medical-grade oxygen onsite. This eliminates logistical challenges and saves them from stocking up pre-filled cylinders. With a series of air filters and a special bacterial filter, MedO produces oxygen within the recommended range of purity (93% ± 3%) even when the intake contains a high concentration of pollutants.

Features

Certified QMS for Medical Devices

FiO2 ranging between

0.90 and 0.96

Global Manufacturing Standards

24x7 Onsite Oxygen Production

Worldwide Pharmacopeia Compliant

Advanced Display & Control System

ROI Less

than 1 Year

Ergonomic & Compact Design

10+ Years Life

Withstands 0-50° Celsius

Certified QMS for Medical Devices

FiO2 ranging between

0.90 and 0.96

Global Manufacturing Standards

24x7 Onsite Oxygen Production

Worldwide Pharmacopeia Compliant

Advanced Display & Control System

ROI Less

than 1 Year

Ergonomic & Compact Design

10+ Years

Life

Withstands 0-50° Celsius

Benefits

Consistent Supply

Consistent Supply

Working Gas Separation

This process uses atmospheric air (20.9% oxygen, 78% nitrogen, 0.9 % argon and 0.2% other gases) to produce life-saving O2. It mainly involves four stages:

Absstem’s medical oxygen generator uses only atmospheric air as raw material. Medical oxygen generator consists of two adsorbers filled with zeolite molecular sieves. Pressurized air is passed through one of these adsorbers, zeolite having a structure to attract nitrogen, adsorbs itrogen from air and oxygen is allowed to pass through to the storage tank and is produced as the final product. As adsorber approaches saturation, air is allowed to pass through the other adsorber while this adsorber is being regenerated to ensure a continuous supply of medical oxygen. This changeover takes place through a specially designed micro controller to ensure a hassle free operation. The quality of oxygen produced is continuously monitored by an oxygen analyzer.

Engineering

The integral components of MedO include: –

Refrigeration Dryer - Removes water vapour from compressed air

Air Tank - Removes moisture and minimizes pulsation

Multistage Filtration System - Decontaminates the compressed air

Inlet Air Monitoring System - Eradicates molecular sieve contamination

PSA System - Generates Oxygen

Storage System - Stores the produced oxygen

HEPA Filter - Removes bacterial contamination

Design

We have designed our products to cater to the needs of both Indian and international markets. All our systems come equipped with a touchscreen monitor for easier operation. There’s a purity analyzer to ensure the supply of pure oxygen while being compliant with the European, US and Indian Pharmacopeia. To eliminate any potential space issues, our engineers have worked relentlessly to make sure our oxygen generators have compact form factors.

STATS Technical Data

Inlet air as per ISO 8573.1:2010 - Class 1.4.1

Medical grade conforming to US, EU, UK and Indian pharmacopoeia

Pressure up to 200 kg/cm2g is available on demand through oxygen compressors

Sound Level of 65 dB from a distance of 1 meter.

Oxygen flow is 2.5 to 250 Nm3/hr

O2 Delivery Pressure is 5.3 barg

Oxygen dew point is -500C

USB Storage is available to store parameters values.

CE certified electrical & electronics with 24 VDC operating Voltage.

All tanks are fabricated per ASME standards.

All tanks have corrosion-resistant internal environment.

ISO 9001 2015: Manufacturing is in accordance with certified QMS Quality Management System.

Working temperature -50C to 450C

Power Supply is 230 VAC, 50/60 Hz

Oxygen concentration of Absstem MedO is 93(±3)%. Higher purities (95% and above) are available on demand.

Systems Packaged Solutions

Skid System

This system comes with a compressor, multistage filtration system and de-greased storage vessel.

This is a compact and mobile oxygen generator.

It’s a complete package with all instruments required for oxygen generation.

Container PSA System

Skid mounted mobile systems with complete piping and interlocking support.

Advanced designed for army or areas prone to natural disasters.

Cylinder filling option with noise control for multiple location delivery.

Compressor Auxiliary Equipment

High-pressure Oxygen Compressor

Our high-pressure oxygen compressor is suitable for the production of medical-grade oxygen on larger scales. It comes with a reliable motor that has been specifically designed for superior life.

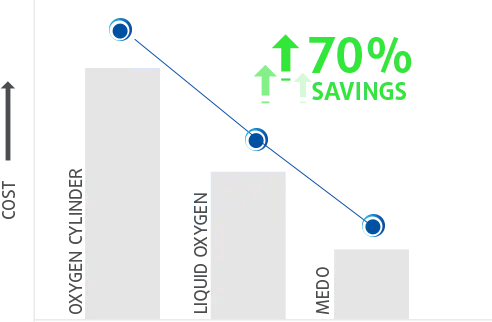

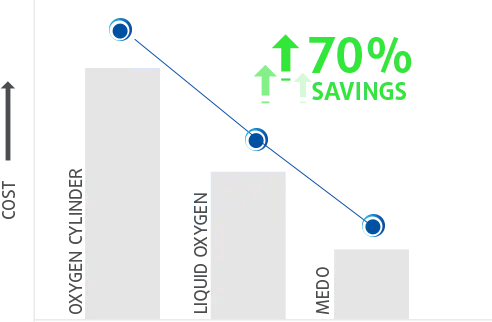

ROI Return on Investment

With great emphasis on cost-effective, low-impact business practices, most businesses opt for bulk delivery to meet all their gas requirements. But given the fluctuation in market prices of gases like oxygen and nitrogen, this is no more a viable option. Absstem’s medical oxygen plants give the best ROI with reliability and peace of mind.

ROI Return on Investment

With great emphasis on cost-effective, low-impact business practices, most businesses opt for bulk delivery to meet all their gas requirements. But given the fluctuation in market prices of gases like oxygen and nitrogen, this is no more a viable option. Absstem’s medical oxygen plants give the best ROI with reliability and peace of mind.

Utilities Applications

Hospitals & Clinics

One of the most used gases in hospitals is Oxygen. Be it ventilators, ICUs, or oxygen therapy – they all need oxygen. Absstem’s custom-designed MedO unit provides a continuous supply of oxygen that is produced on-site.

With ISO certifications, our generators give consistent oxygen output at the exact required purity levels. There are neither hassles for refilling or transportation of the cylinders, nor the constant stress of potential downtimes, delays, variations in purity and pressure outputs.

Hospitals become independent from oxygen cylinders, once in-house oxygen plants are installed.

Army Field/Hospital

We have developed our oxygen generators keeping in mind the oxygen requirements in remote areas of the country where our frontline troops are deployed. It is practically not possible to set up fully-functional hospitals with all the advanced medical facilities at such locations. But it is relatively easier to install onsite oxygen generators at such places so that people who are fighting for us have enough supply of the life-saving O2 if and when required.

We have different installation schemes to suit the requirements of both army hospitals and temporary medical facilities built-in battlefields.

Medical Cylinder Filling

At times, it is better to keep sufficient stock of pre-filled oxygen cylinders as it can help a medical facility meet its fluctuating need for medical-grade oxygen. Our compact yet efficient medical oxygen plant can help you to fill a large number of cylinders in one day so that you do not face issues like inadequate supply.

Brochure Download

FAQs Frequently Asked Questions

Medical Oxygen Plant in India is installed and running at various Hospitals in India. Medical-grade oxygen produced by the Medical oxygen plant is supplied to ICUs (Intensive Care Units) and OTs (Operation Theaters). It is also provided during anaesthesia as a substitute for nitrous oxide to reduce the high concentration of oxygen exposure. Presently the source of medical oxygen is a cylinder manifold. Now, smart hospitals are receiving the benefits of medical oxygen generators using an onsite Medical oxygen gas generator and a backup of cylinders. Hospitals globally realise that onsite medical oxygen generators provide a highly reliable and economical solution. An onsite oxygen plant is a solution for their patients’ oxygen requirements. It eliminates the expense of purchasing, receiving, and monitoring your hospital’s oxygen supply. Costly daily refilling, manual handling injuries, and expensive cylinder stocking add to the expense. Bottled gas delivery can also be very costly if the oxygen supplier is in a remote location.

Medical Oxygen Generators are life-saving machines for hospitals with medical grade oxygen, standardised as per the nation’s requirements, i.e. 93%-96%. Onsite Medical grade PSA oxygen generators are safe, reliable, and durable, providing 24*7 continuous Oxygen to the patient beds. There is no interruption, blockage, hazardous condition, or irregularity using MedO. Hospitals with traditional procurement methods using cylinders or bulk liquid oxygen tanks experience troubles periodically. Several oxygen generators will suit your needs, whether your hospital’s requirements are 99%, 95% or 90%. See different oxygen percentages per country pharmacopoeia. The technology used to produce medical-grade Oxygen is Pressure Swing Adsorption. Compressed air is passed, and Oxygen comes out as product gas from one PSA bed while the other PSA bed is simultaneously regenerated by depressurization to atmospheric pressure.

The reason smart hospitals are already adopting on-site Medical Oxygen generators is that these machines are saving money and lives, plus hospitals never have to care about the service part. The service requirement for the Medical Oxygen plant is minimal. It is not very important compared to the various tasks and operations required by a manifold of cylinders or bulk Liquid oxygen tanks/bottles. The US army is already using Medical Oxygen Generator technology in Army hospitals. Hence the technology’s safety and reliability are never questioned. All you need to find is the right company that can supply you with the product with the finest service support you can ever imagine. See benefits of Medical Oxygen Generator.

The best alternative to supply medical-grade oxygen to hospitals is by producing it on-site. Medical Oxygen Generator for hospitals in India comes in different sizes and packages. The design is uniform to provide hospitals with an International world-class experience. The Medical Oxygen generator comes with an Online Oxygen Analyzer to check the purity of Oxygen, ensuring everything is operational per the Hospital standards plus complying with the Indian Pharmacopoeia standards.

Standard Scheme: The standard scheme has a Medical Oxygen generator plant with a Cylinder manifold system as a backup supply. Using the existing Medical Oxygen Gas Pipeline System (MOGPS), the Medical Oxygen plant is connected directly to it. The Switchover panel acts as a control system. It switches to the cylinder manifold, the backup supply for the Medical Oxygen plant. Premium Scheme: The premium scheme is the most popular arrangement. Two Medical Oxygen generators are connected while the other acts as a backup. Also, a cylinder manifold is connected for further emergency backup. Big Hospitals have thousands of patients visiting each day. Such hospitals look for higher Oxygen demands with the safest method. No hospital can afford any risk

Oxygen Purity: Medical Oxygen generators come with an Online Oxygen Analyzer that displays the Oxygen purity all the time. Continuous Flow: First, a continuous, uninterrupted supply of Medical Oxygen is the most important thing. The Medical Oxygen Generator comes with a Flowmeter to make sure it happens. This instrument continually provides continuous, uninterrupted Medical grade oxygen to the patient beds. Audio Visual Alarms: Any unusual activity will horn the alarm, thus avoiding erroneous situations. Absstem ensures the well-being of the hospital since it is our first goal. Furthermore, any undesirable sign will activate the alarms equipped in the Medical Oxygen Generator. In addition, the alarms are generated to lead the operator to reach the site location. The operator, therefore, contacts . Special Filtration: MedO comes with a series of air and a special Bacterial Filter to ensure that Medical Oxygen supplied to your hospital is free of all impurities.

Medical Oxygen Gas Generator is the heart of the healthcare sector and is blessed with PSA technology. All hospitals run using Medical oxygen, and without medical-grade oxygen, one cannot operate gas. The low budget of small hospitals and less requirement of medical grade oxygen is the reason. Some companies provide customised small Medical Oxygen Generators to ensure no hospital is unseen. This Medical Oxygen Generator is the primary Oxygen supply for very small hospitals. Small hospitals with 3 or 4 beds use this Medical Oxygen plant. The secondary set-up (cylinders or Liquid Oxygen bottles) is used as a backup. Based on facts and studies, onsite Medical oxygen generators are already used by hospitals worldwide.

Bottled gases & Liquid gases are subject to fluctuating prices

Bottled gases & Liquid gases are subject to fluctuating prices Weekly or monthly transportation charges are huge

Weekly or monthly transportation charges are huge Delivered gases and cylinders are heavy, burdensome and often troublesome

Delivered gases and cylinders are heavy, burdensome and often troublesome Delivered gas supply can be irregular, causing disruptions in.

Delivered gas supply can be irregular, causing disruptions in. A lot of vendors are sitting in remote locations.

A lot of vendors are sitting in remote locations. Bottled gas delivery to hospitals is very costly plus time consuming.

Bottled gas delivery to hospitals is very costly plus time consuming. Hospitals run out of medical oxygen using cylinders. 24×7 care from operators is very important.

Hospitals run out of medical oxygen using cylinders. 24×7 care from operators is very important. Gases stored in cylinders are at a pressure which is dangerous for life.

Gases stored in cylinders are at a pressure which is dangerous for life.